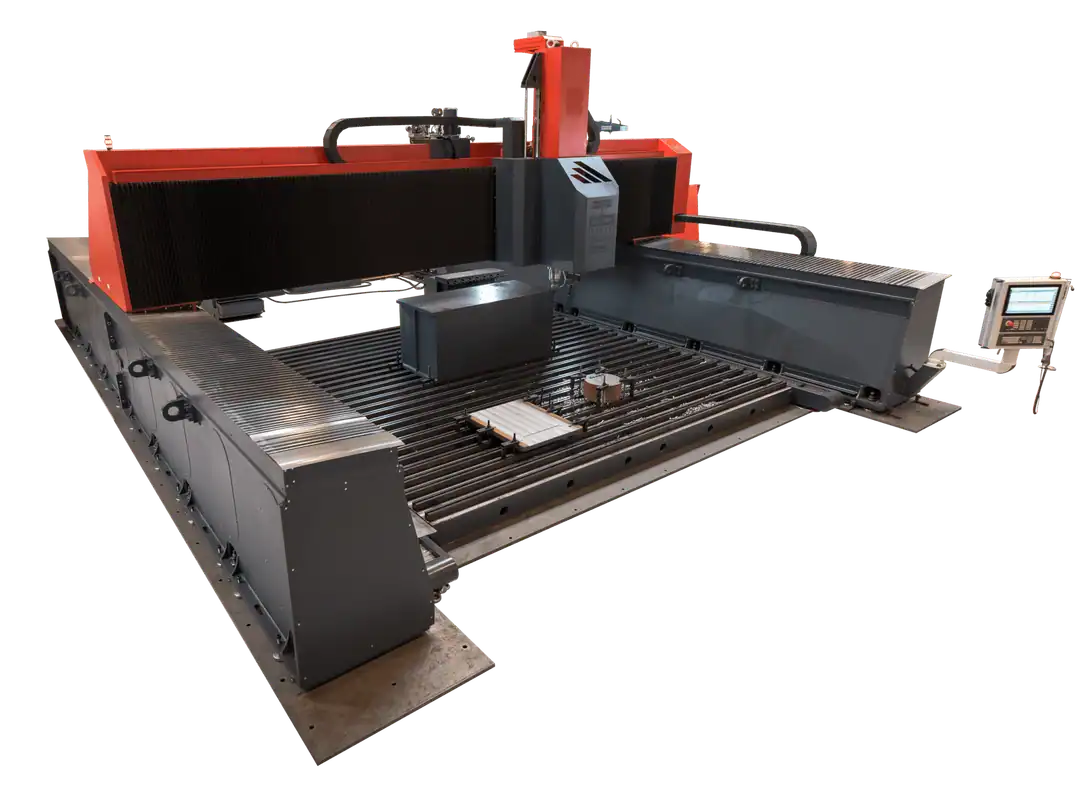

Akyapak CNC Gantry Milling Machine

Maximize Production, Minimize Challenges: Reliable Solutions for Heavy Part Processing

Capabilities

ARTOS offers precision, speed and reliability in processing complex, large parts.

Elevating Performance for the Heaviest Challenges

Understanding the varied needs of our customers, we design and create our machines to meet these specific requirements. Our focus lies in plate processing where we emphasize on speed and advanced automation. We offer an array of advanced machinery for drilling, milling, countersinking, tapping, and marking to maximize production output. Especially in the steel processing sector, our machines offer the most reliable solutions for processing large and challenging parts. This is made possible through the combined efforts of our robust mechanical features and advanced automation capabilities.

Drilling

With a hole drilling capacity of 11.8” (300mm), it effectively reduces production time below standard rates, enabling more efficient production in a shorter time span.

Automatic Tool Changer

The 8-station tool holder enables tool change without the need for manual intervention.

Material Clamping

The clamping process effectively minimizes vibration by securing the material at eight different points with a T Channel clamping table. This not only prevents the wear of the tool tips, but also significantly extends their service life.

Excellent Surface Roughness Quality

ARTOS ensures zero tolerance and smooth workpiece finish for quality milling.

Step Cutting

Step cutting allows drilling regardless of height due to its stepped process. By turning the material on the table, It can drill holes on both sides, regardless of the height.

Multiple Processing and Speed

ARTOS outperforms standard machines due to its plate processing design, using the traveling bridge process to efficiently process material at all points.

Cooling

The high cooling capability of ARTOS extends tool bit life and reduces costs.

| Technicial Specifications | APD |

|---|---|

| Drilling Diameter (mm) | Carbide 10-40 / U tool 40-75 (25/64 Carbide / 37/64 U Tool – Inch ) |

| Spindle Speed | 10 – 3000 rpm |

| Spindle Power | 30 kW ( 40 hp ) |

| Automatic Tool Changer | 8 – Station |

| Thread Tapping | M12 – M30 |

| Tool Holder | BT50 |

| Material Width | 5000 x 5000 ( 197×197 Inch ) |

| Work Piece Weight (Kg) | 30.000 ( 66.139 lbs ) |