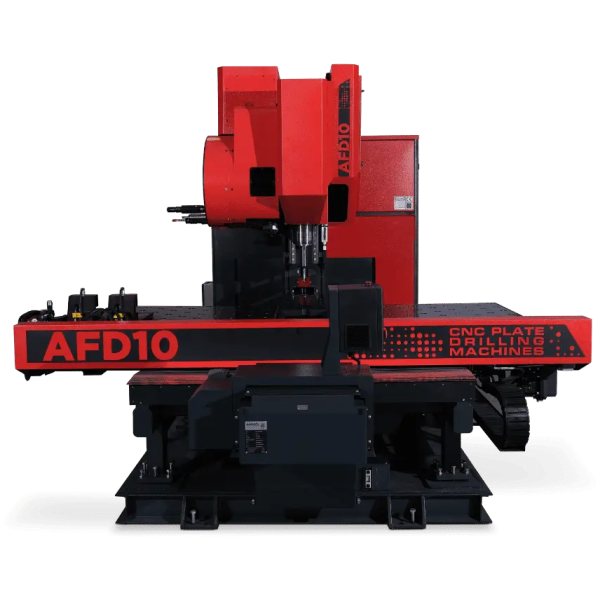

Akyapak Plate Drilling Machine

AFD has carbide drilling, countersinking, marking, tapping, milling features. You can drill holes at high-speed thanks to carbide bits. With the AFD, you can easily process with a width of 1,000mm a thickness of 80mm and a maximum weight of 750kg.

Catch Perfection High Speed Carbide

Drilling Quality

AFD plate drilling machines revolutionize the manufacturing landscape for small and medium-sized steel producers. Designed to propel your operation into a new era of efficiency, these machines offer an unparalleled blend of speed and precision. With advanced processing technologies including milling, drilling, countersinking, tapping, and marking, these machines are not just tools, but gateways to maximizing your production output. Experience minimal downtime and witness a significant leap in productivity, as AFD plate drilling machines streamline your operations and deliver flawless results, every single time. Transform the way you work and outshine the competition with these powerhouse machines at your disposal.

High Automation

Meet demanding manufacturing schedules and maintain competitive edge with AFD’s high automation capabilities. The AFD significantly enhances precision of processes such as drilling, milling, marking, tapping and countersinking, leading to improved productivity and consistent quality in the production cycle.

Automatic Tool Changer

The AFD comes with a 16-tool capacity tool changing unit. This allows for easy tool changes without the need for manual intervention. It also minimizes machine downtime by reducing the operator’s workload.

Carbide Drilling

Carbide drills stand out by delivering an unparalleled combination of high precision, making them the preferred choice for demanding applications. The versatility of carbide drill bits is displayed by the broadest range of diameters available, catering to end-users who desire an extended tool lifespan across a variety of materials. The ability of the AFD to meet this need not only boosts efficiency, but also promotes durability in various drilling situations.

Material Clamping

The AFD has two adjustable hydraulic clamps that precisely position plates using servo-driven ball screws that move in both X and Y directions, ensuring a secure fit. By doing so, the system effectively minimizes potential vibrations during operation, thereby protecting the tool bits and maximizing operational efficiency. The clamps provide excellent hold on the plates, and the distance between the two can be adjusted to accommodate both small and large plates.

Automatic Tool and Material Measurement

The AFD comes with an automatic tool and material measurement feature, allowing operators to input the type of material and its dimensions. The machine uses lasers to find a zero reference point for the material and automatically measure the length of the tool.

Software

AKPOST is a unique software designed to produce G-codes for AFD models and is compatible with Mitsubishi and Siemens controllers. The software can also import DXF and DSTV files and is designed with a simple-to-use interface, making it easy for even a novice operator to learn and use quickly.

| Technicial Specifications | AFD 07 | AFD 10 |

|---|---|---|

| Capabilities | Drilling – Milling -Tapping – Contersinking – Scribe Marking | Drilling – Milling -Tapping – Contersinking – Scribe Marking |

| Spindle Power | 22 kW ( 30 hp) | 22 kW ( 30 hp) |

| Spindle Speed | 10 – 3000 rpm | 10 – 3000 rpm |

| Tool Holder | BT40 | BT40 |

| Thread Tapping | M10 – M24 | M10 – M24 |

| Min Material Size | 200 x 200 x 6 ( 8 x 8 x 1/4 Inch ) | 100 x 100 x 6 ( 4 x 4 x 1/4 Inch ) |

| Max Material Size | 700 x 1250 x 40 ( 27.6 x 49.2 x 1-9/16 Inch ) | 1000 x 1190 x 80 ( 40 x 47 x 3-1/8 Inch ) |

| Min-Max Material Thickness | 6 – 80 ( 1/4 – 3-1/8 Inch ) | 6 – 80 ( 1/4 – 3-1/8 Inch ) |

| Max Moveable Material Weight | 500 ( 1100 lbs ) | 750 ( 1650 lbs ) |