Flap Wheel Mounted 40, 50 or 60mm Diameter

€6.43 Inc Vat

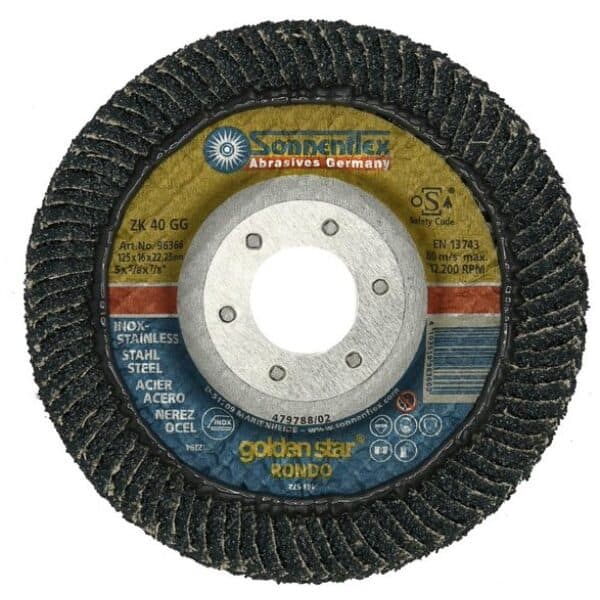

A flap wheel is made of multiple overlapping small pieces or ‘flaps’, bonded to a central 6mm spindle.

Our Kronenflex Flap wheels are the highest quality and represent the best value in cost to performance ratio.

This wheel is a mixture of different grit zirconium flaps from 80 to 150 grit and red (course) scotchbrite.

The separate flaps each attack the workpiece surface at a slightly different angle, and this varies slightly with tool angle.

This avoids the common problem with flat sheets, where they produce repeated identical scratches.

Abrasive wear is distributed more evenly across the flaps, and through the length of each flap.

Flap wheels wear from their outer ends and the sheet carrier cuts back as the abrasive coating is worn away.

The Flap wheel remains useful even as the flaps erode.

Compared to flat sheets, that are discarded after only a small area of the abrasive is truly worn-out, a flap wheel is a much more efficient use of the abrasive material.

You must be logged in to post a review.

Reviews

There are no reviews yet