7 Ways on How to Save (Money) on your Welding Gas

Using welding gas can sometimes amount to a considerable cost while welding, but there are a number of ways where you can reduce your gas consumption and thus save you money. Gas is used in welding to create ‘shielding’ – the purpose of which is to protect the weld area from oxygen and water vapour. If these are present then these natural gases in the atmosphere can actually distort the weld, give a poor quality weld and generally make it harder to weld with accuracy.

We have compiled 7 ways to help you combat some of the problems and save on your welding gases, giving you better results and/or saving you money.

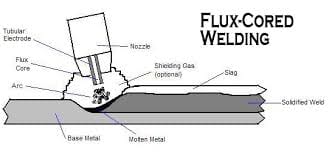

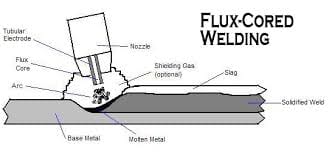

1. Flux Core Wire The most obvious way is not to use any gas at all, and simply use a flux core wire instead of gas while mig

welding. This is fine perhaps for someone starting off learning to weld, but eventually you will require gas to give you better, cleaner welds. The flux core wire will not give as nice a weld as when using gas to weld, as it will leave a residue behind that will require chipping after to remove it. It also requires higher amperage to melt it properly so it’s unsuitable for light material under 3mm thick. Check out our gasless flux cored wire products for mig welding below:

View Mig Wire

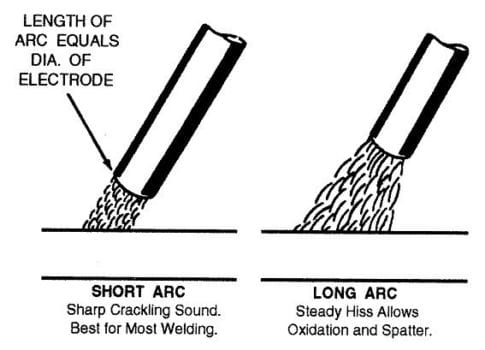

2. Shorten Your Arc

The most obvious way is not to use any gas at all, and simply use a flux core wire instead of gas while mig

welding. This is fine perhaps for someone starting off learning to weld, but eventually you will require gas to give you better, cleaner welds. The flux core wire will not give as nice a weld as when using gas to weld, as it will leave a residue behind that will require chipping after to remove it. It also requires higher amperage to melt it properly so it’s unsuitable for light material under 3mm thick. Check out our gasless flux cored wire products for mig welding below:

View Mig Wire

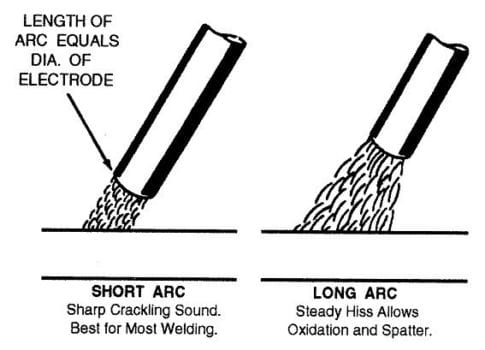

2. Shorten Your Arc This seems like a simple suggestion but the closer your welding tip and shroud are to the weld, the

better. If your stick-out is 20 to 30mm away from the weld you are just using a lot of gas to shield your weld. Keep turning your Flow Meter down until just before porosity occurs in the weld. If porosity does occur in weld turn up the Flow Meter until you are using just a little more than is required.

3. CO2 versus a CO2 & Argon mix

While using a mix of CO2 and Argon will typically give better weld results, it is a more expensive gas to buy. Many will avoid using 100% CO2 as its results can create more splatter when welding – but it is cheaper. With that said if you can find a good balance between wire speed and the voltage, then welding with CO2 can give minimal splatter. If using an inverter machine it may have settings programmed for use with only CO2 gas.

4. Gas Regulators

This seems like a simple suggestion but the closer your welding tip and shroud are to the weld, the

better. If your stick-out is 20 to 30mm away from the weld you are just using a lot of gas to shield your weld. Keep turning your Flow Meter down until just before porosity occurs in the weld. If porosity does occur in weld turn up the Flow Meter until you are using just a little more than is required.

3. CO2 versus a CO2 & Argon mix

While using a mix of CO2 and Argon will typically give better weld results, it is a more expensive gas to buy. Many will avoid using 100% CO2 as its results can create more splatter when welding – but it is cheaper. With that said if you can find a good balance between wire speed and the voltage, then welding with CO2 can give minimal splatter. If using an inverter machine it may have settings programmed for use with only CO2 gas.

4. Gas Regulators There are a number of different types of gas regulators, such as, single stage 1 and single stage 2 gauges. Single stage 1 shows the amount of gas left in the bottle, while a single stage 2 shows the amount of gas in litres per minute that is being used, as well as the what is left in your bottle. For optimum savings used a flow meter with a single stage 2 regulator. View our gas regulators:

View Gas Regulators

5. Flow Meters

There are a number of different types of gas regulators, such as, single stage 1 and single stage 2 gauges. Single stage 1 shows the amount of gas left in the bottle, while a single stage 2 shows the amount of gas in litres per minute that is being used, as well as the what is left in your bottle. For optimum savings used a flow meter with a single stage 2 regulator. View our gas regulators:

View Gas Regulators

5. Flow Meters The merits of a flow meter are quite simple. While the regulator will show the amount of gas going from the bottle to the torch, the flow meter has a controlling knob to either lower or higher the amount and set it to an even amount for the duration of your welding. The benefit here is that there will be no added surges in gas, which typically happens when starting to weld (after being idle). For such a simple (and cheap) product this can save large amounts of gas over time and ultimately save you money.

View Flowmeters

6. IGC® – Intelligent Gas Control from Migatronic

The merits of a flow meter are quite simple. While the regulator will show the amount of gas going from the bottle to the torch, the flow meter has a controlling knob to either lower or higher the amount and set it to an even amount for the duration of your welding. The benefit here is that there will be no added surges in gas, which typically happens when starting to weld (after being idle). For such a simple (and cheap) product this can save large amounts of gas over time and ultimately save you money.

View Flowmeters

6. IGC® – Intelligent Gas Control from Migatronic

Some of our Migatronic welders have an in-built Intelligent Gas Control (IGC®) system, and these can be found in the Sigma Galaxy range (below). How does it work? The technology monitors gas consumption and optimises gas protection. At the beginning of the weld process, the IGC® function prevents over-consumption of gas and gives a good initial performance. Once the weld pool is established the IGC® takes control, ensuring extensive savings thanks to the controlled gas consumption that is optimised according to current needs.

View the Sigma Galaxy Range

Find out more: Migatronic IGC technology.

Also learn about: Migatronic IAC (Intelligent Arc Control) technology.

7. Welding Gases – Rent Free from ProWeld

Some of our Migatronic welders have an in-built Intelligent Gas Control (IGC®) system, and these can be found in the Sigma Galaxy range (below). How does it work? The technology monitors gas consumption and optimises gas protection. At the beginning of the weld process, the IGC® function prevents over-consumption of gas and gives a good initial performance. Once the weld pool is established the IGC® takes control, ensuring extensive savings thanks to the controlled gas consumption that is optimised according to current needs.

View the Sigma Galaxy Range

Find out more: Migatronic IGC technology.

Also learn about: Migatronic IAC (Intelligent Arc Control) technology.

7. Welding Gases – Rent Free from ProWeld

We have another option for you, in the form of Rent Free Welding Gas. This may not suit everyone as it will depend on how often you weld, or how often you need to replace your gas bottles. With our method, you pay a once-off price for a new 5L, 9L or 20L gas bottle. Included in the price is a deposit – which is refundable to you – if you decide you don’t want or need the bottle anymore. This may work out cheaper for you than other methods, but will depend on your welding gas usage.

When your finish your gas bottle, but need a refill, simply return it to us and we will supply you with a new bottle. This can be undertaken by our delivery service. If you wish to view our rent free welding gases:

View Welding Gases

So, hopefully there is something in there that can help you save on your gas consumptions while welding!

Image credits:

Flux Cored Welding – www.weldersuniverse.com

Short Arc – www.wcwelding.com

Migatronic IGC: http://www.migatronic.com/

We have another option for you, in the form of Rent Free Welding Gas. This may not suit everyone as it will depend on how often you weld, or how often you need to replace your gas bottles. With our method, you pay a once-off price for a new 5L, 9L or 20L gas bottle. Included in the price is a deposit – which is refundable to you – if you decide you don’t want or need the bottle anymore. This may work out cheaper for you than other methods, but will depend on your welding gas usage.

When your finish your gas bottle, but need a refill, simply return it to us and we will supply you with a new bottle. This can be undertaken by our delivery service. If you wish to view our rent free welding gases:

View Welding Gases

So, hopefully there is something in there that can help you save on your gas consumptions while welding!

Image credits:

Flux Cored Welding – www.weldersuniverse.com

Short Arc – www.wcwelding.com

Migatronic IGC: http://www.migatronic.com/

The most obvious way is not to use any gas at all, and simply use a flux core wire instead of gas while mig

welding. This is fine perhaps for someone starting off learning to weld, but eventually you will require gas to give you better, cleaner welds. The flux core wire will not give as nice a weld as when using gas to weld, as it will leave a residue behind that will require chipping after to remove it. It also requires higher amperage to melt it properly so it’s unsuitable for light material under 3mm thick. Check out our gasless flux cored wire products for mig welding below:

View Mig Wire

2. Shorten Your Arc

The most obvious way is not to use any gas at all, and simply use a flux core wire instead of gas while mig

welding. This is fine perhaps for someone starting off learning to weld, but eventually you will require gas to give you better, cleaner welds. The flux core wire will not give as nice a weld as when using gas to weld, as it will leave a residue behind that will require chipping after to remove it. It also requires higher amperage to melt it properly so it’s unsuitable for light material under 3mm thick. Check out our gasless flux cored wire products for mig welding below:

View Mig Wire

2. Shorten Your Arc This seems like a simple suggestion but the closer your welding tip and shroud are to the weld, the

better. If your stick-out is 20 to 30mm away from the weld you are just using a lot of gas to shield your weld. Keep turning your Flow Meter down until just before porosity occurs in the weld. If porosity does occur in weld turn up the Flow Meter until you are using just a little more than is required.

3. CO2 versus a CO2 & Argon mix

While using a mix of CO2 and Argon will typically give better weld results, it is a more expensive gas to buy. Many will avoid using 100% CO2 as its results can create more splatter when welding – but it is cheaper. With that said if you can find a good balance between wire speed and the voltage, then welding with CO2 can give minimal splatter. If using an inverter machine it may have settings programmed for use with only CO2 gas.

4. Gas Regulators

This seems like a simple suggestion but the closer your welding tip and shroud are to the weld, the

better. If your stick-out is 20 to 30mm away from the weld you are just using a lot of gas to shield your weld. Keep turning your Flow Meter down until just before porosity occurs in the weld. If porosity does occur in weld turn up the Flow Meter until you are using just a little more than is required.

3. CO2 versus a CO2 & Argon mix

While using a mix of CO2 and Argon will typically give better weld results, it is a more expensive gas to buy. Many will avoid using 100% CO2 as its results can create more splatter when welding – but it is cheaper. With that said if you can find a good balance between wire speed and the voltage, then welding with CO2 can give minimal splatter. If using an inverter machine it may have settings programmed for use with only CO2 gas.

4. Gas Regulators There are a number of different types of gas regulators, such as, single stage 1 and single stage 2 gauges. Single stage 1 shows the amount of gas left in the bottle, while a single stage 2 shows the amount of gas in litres per minute that is being used, as well as the what is left in your bottle. For optimum savings used a flow meter with a single stage 2 regulator. View our gas regulators:

View Gas Regulators

5. Flow Meters

There are a number of different types of gas regulators, such as, single stage 1 and single stage 2 gauges. Single stage 1 shows the amount of gas left in the bottle, while a single stage 2 shows the amount of gas in litres per minute that is being used, as well as the what is left in your bottle. For optimum savings used a flow meter with a single stage 2 regulator. View our gas regulators:

View Gas Regulators

5. Flow Meters The merits of a flow meter are quite simple. While the regulator will show the amount of gas going from the bottle to the torch, the flow meter has a controlling knob to either lower or higher the amount and set it to an even amount for the duration of your welding. The benefit here is that there will be no added surges in gas, which typically happens when starting to weld (after being idle). For such a simple (and cheap) product this can save large amounts of gas over time and ultimately save you money.

View Flowmeters

6. IGC® – Intelligent Gas Control from Migatronic

The merits of a flow meter are quite simple. While the regulator will show the amount of gas going from the bottle to the torch, the flow meter has a controlling knob to either lower or higher the amount and set it to an even amount for the duration of your welding. The benefit here is that there will be no added surges in gas, which typically happens when starting to weld (after being idle). For such a simple (and cheap) product this can save large amounts of gas over time and ultimately save you money.

View Flowmeters

6. IGC® – Intelligent Gas Control from Migatronic

Some of our Migatronic welders have an in-built Intelligent Gas Control (IGC®) system, and these can be found in the Sigma Galaxy range (below). How does it work? The technology monitors gas consumption and optimises gas protection. At the beginning of the weld process, the IGC® function prevents over-consumption of gas and gives a good initial performance. Once the weld pool is established the IGC® takes control, ensuring extensive savings thanks to the controlled gas consumption that is optimised according to current needs.

View the Sigma Galaxy Range

Find out more: Migatronic IGC technology.

Also learn about: Migatronic IAC (Intelligent Arc Control) technology.

7. Welding Gases – Rent Free from ProWeld

Some of our Migatronic welders have an in-built Intelligent Gas Control (IGC®) system, and these can be found in the Sigma Galaxy range (below). How does it work? The technology monitors gas consumption and optimises gas protection. At the beginning of the weld process, the IGC® function prevents over-consumption of gas and gives a good initial performance. Once the weld pool is established the IGC® takes control, ensuring extensive savings thanks to the controlled gas consumption that is optimised according to current needs.

View the Sigma Galaxy Range

Find out more: Migatronic IGC technology.

Also learn about: Migatronic IAC (Intelligent Arc Control) technology.

7. Welding Gases – Rent Free from ProWeld

We have another option for you, in the form of Rent Free Welding Gas. This may not suit everyone as it will depend on how often you weld, or how often you need to replace your gas bottles. With our method, you pay a once-off price for a new 5L, 9L or 20L gas bottle. Included in the price is a deposit – which is refundable to you – if you decide you don’t want or need the bottle anymore. This may work out cheaper for you than other methods, but will depend on your welding gas usage.

When your finish your gas bottle, but need a refill, simply return it to us and we will supply you with a new bottle. This can be undertaken by our delivery service. If you wish to view our rent free welding gases:

View Welding Gases

So, hopefully there is something in there that can help you save on your gas consumptions while welding!

Image credits:

Flux Cored Welding – www.weldersuniverse.com

Short Arc – www.wcwelding.com

Migatronic IGC: http://www.migatronic.com/

We have another option for you, in the form of Rent Free Welding Gas. This may not suit everyone as it will depend on how often you weld, or how often you need to replace your gas bottles. With our method, you pay a once-off price for a new 5L, 9L or 20L gas bottle. Included in the price is a deposit – which is refundable to you – if you decide you don’t want or need the bottle anymore. This may work out cheaper for you than other methods, but will depend on your welding gas usage.

When your finish your gas bottle, but need a refill, simply return it to us and we will supply you with a new bottle. This can be undertaken by our delivery service. If you wish to view our rent free welding gases:

View Welding Gases

So, hopefully there is something in there that can help you save on your gas consumptions while welding!

Image credits:

Flux Cored Welding – www.weldersuniverse.com

Short Arc – www.wcwelding.com

Migatronic IGC: http://www.migatronic.com/