What Is Synergic Mig Welding??

There is often confusion regarding this subject. Synergic refers to a machine that sets up the parameters within a selected programme according to Amperage, Wire Feed Speed or material thickness. The machine then sets the volts etc according to the information in the memory of the machine. Many synergic machines have Pulsed or Double Pulsed Arc function, for spatter-free, controlled Mig/Mag welding.

We can use the interface of a basic Migatronic Autopuls² Mig as an example. The top left grey button is to select the material/ gas you are welding. The bottom left grey button is used to select the thickness of the welding wire you are going to use.

Next, using the smaller green button we can select Amps, Wire speed or material thickness by which to adjust our machine. If it is material thickness you simply turn the larger green knob to your desired thickness. The welder is now set to the optimum parameters and has also adjusted the Amp’s and wire feed. This includes the optimum pulse parameters if they are required.

Example:

Select FeCo2 (mild steel) > Select Wire Diameter (1.0mm) > Set Material Thickness (6mm)

Machine is ready to weld at optimum setting.

If the welder is running too hot, adjusting the large green knob back a little will also adjust the wire feed speed and Amps, all in ‘Synergy’ with each other. Do the same if it running too cold.

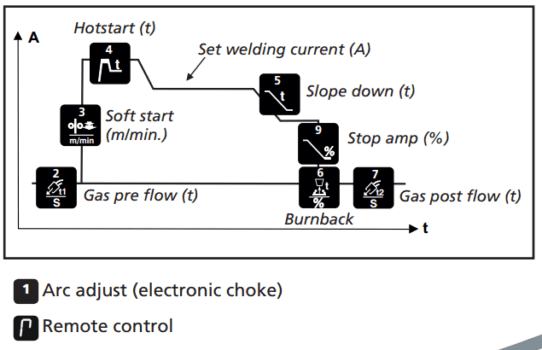

This Migatronic Autopuls also has the additional benefit of being able to fine tune many of the parameters by selecting the bottom right grey button and working through the menu numbered 1 to 9 and adjusting each parameter with the large green knob.

It should be noted that these additional parameters should be automatically set from the machine’s memory

Key Points

- Save time with ‘One knob’ operation

- User friendly- save money on training

- Pulse parameters are selected automatically

- Get the consistant welding results each and every time

You need more information? Why not send me an email to: paul@proweld.ie

For reference the symbols on this interface are as follows:

CuAl = Copper Alloy(Aluminium Bronze Welding)

CuSi = Copper Silicone(Mig Brazing)

Al = Aluminium(4043,4047 & 5356)

FeMix = Mild Steel with Argon Mix Gas

FeCO2 = Mild Steel with Co2 Gas